In the dynamic landscape of machining, machine shops in Houston face increasing demand for the precision machining of advanced materials. This overview explores the unique challenges encountered by machine shop houston when working with advanced materials and outlines the innovative solutions implemented to overcome these challenges.

Challenges in Advanced Materials Machining:

- Material Hardness and Toughness:

Advanced materials, such as titanium alloys and high-strength steels, often exhibit exceptional hardness and toughness. Machining these materials poses challenges related to tool wear, heat generation, and the need for specialized cutting tools.

- Thermal Conductivity:

Some advanced materials have high thermal conductivity, making it challenging to dissipate heat generated during machining. Elevated temperatures can affect tool life, dimensional accuracy, and surface finish.

- Abrasive Properties:

Certain advanced materials, including composites and ceramics, possess abrasive characteristics that accelerate tool wear. This necessitates frequent tool changes, impacting production efficiency and increasing operational costs.

- Dimensional Stability:

Maintaining dimensional stability during machining is crucial, especially for components with tight tolerances. Advanced materials may exhibit dimensional changes due to heat accumulation, impacting the final product’s precision.

Solutions Implemented by Machine Shops:

- Advanced Cutting Tools:

Machine shops in Houston invest in state-of-the-art cutting tools, including coated carbide and ceramic inserts, designed specifically for machining advanced materials. These tools enhance wear resistance and heat dissipation, improving overall machining performance.

- Coolant Strategies:

Innovative coolant strategies, such as high-pressure coolant systems and cryogenic machining, are employed to manage heat generated during machining. This ensures improved tool life, dimensional stability, and enhanced surface finishes.

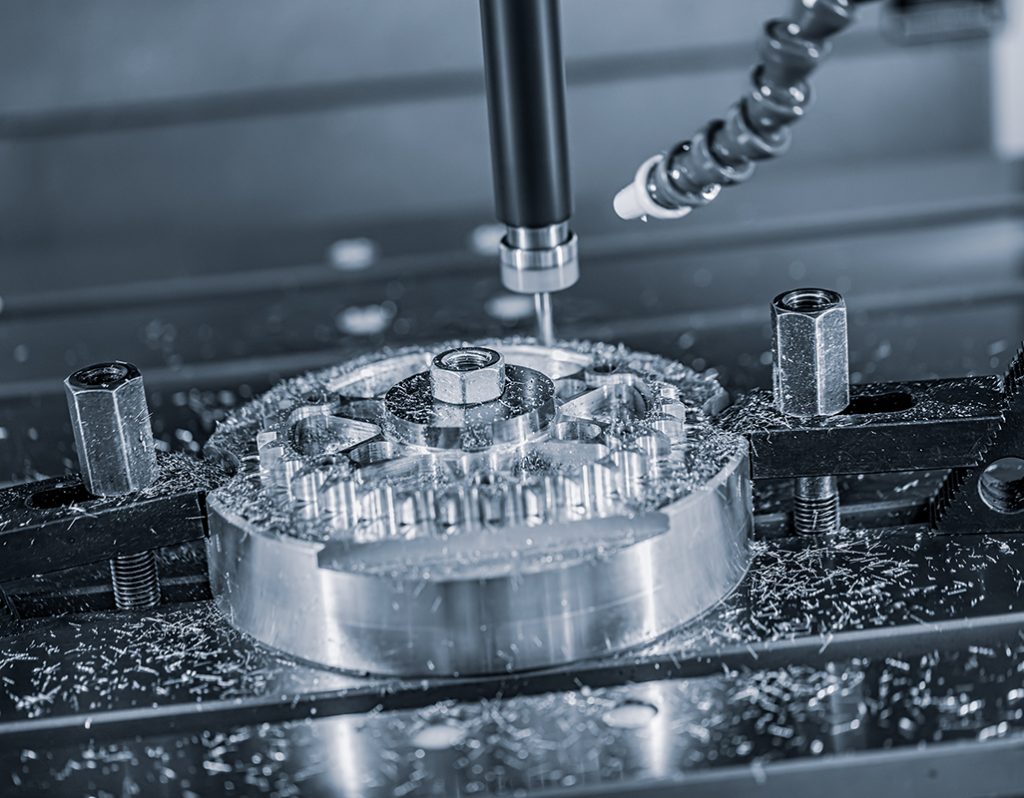

- Precision Machining Techniques:

Implementing precision machining techniques, such as multi-axis machining and high-speed machining, allows machine shops to achieve intricate details and tight tolerances in components made from advanced materials.

- In-Process Monitoring and Quality Control:

To address challenges related to dimensional stability, machine shops employ in-process monitoring and advanced quality control measures. Real-time feedback allows for adjustments, ensuring that machined components meet or exceed specified tolerances.

Conclusion:

The machine shop Houston demonstrate resilience and innovation in addressing the challenges associated with machining advanced materials. Through the adoption of advanced cutting tools, coolant strategies, precision machining techniques, and collaborative partnerships, these machine shops are well-positioned to meet the evolving demands of industries requiring the precision machining of advanced materials.